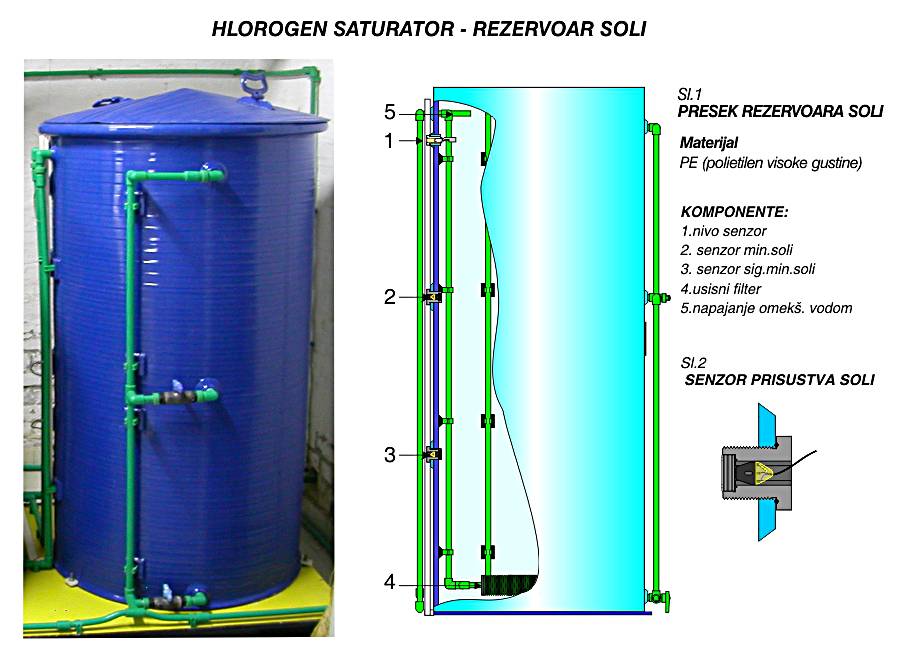

Salt saturator contains moisten salt and above is saturated brine solution. This solution goes through filter and suction basket to solenoid dosing pump which pumps it into the electrolyzer. Saturated brine is also used for regeneration of the water softener. Diluted solution for the electrolytic process (3% of NaCl) is created by mixing with exact quantity of softened water. It has the indicator of the minimum salt level, which signalizes when refilling is needed.

Salt saturator should be refilled with the salt when it is signalized on the display or on the PC monitor. Salt saturator also has a level indicator for automatic refilling of the softened water. When the salt level drops to the minimum, solenoid valve for refilling the salt saturator with the softened water closes water supply.

PRESENCE OF SALT Sensor

Sensor detects the presence of light (white) surface. In the infrared sensor аre embedded receiver and transmitter. Infrared transmitter and receiver are each set at an angle of 20 degrees. If the surface is light, emitted IR beam reflects and falls on the receiver. It does not reflect if the surface is dark or does not exist. Nominal distance of sensor is 3-5mm. Driver electronics is located in sensors relay housing with potentiometer for adjustment of sensitivity and relay output to drive installed automatic.